Why cell-free?

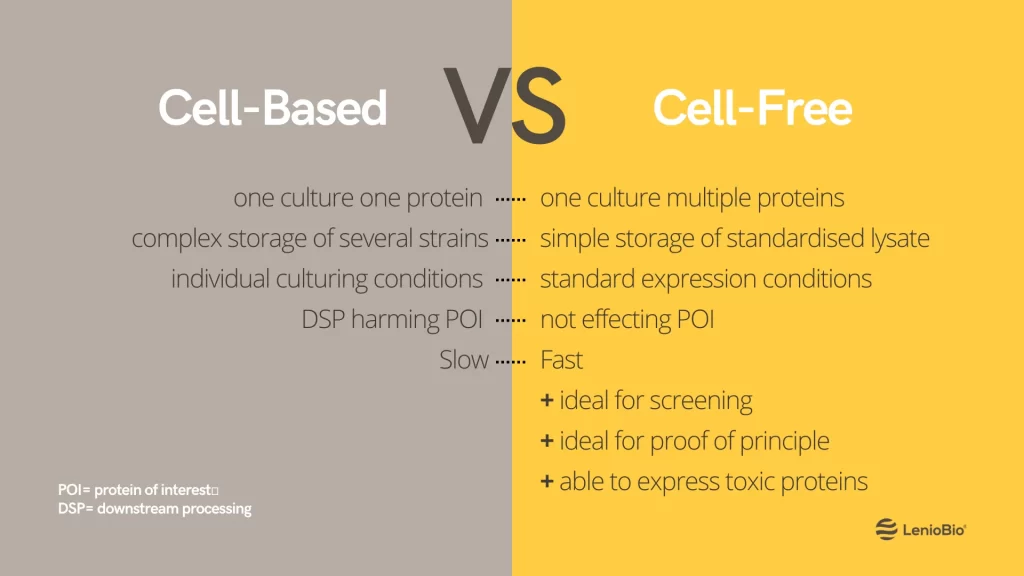

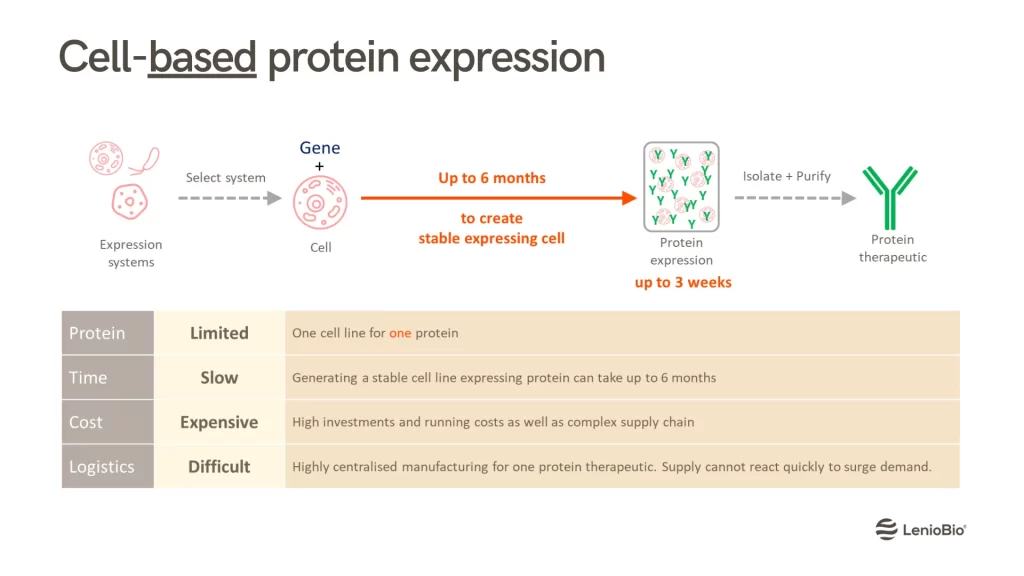

Traditional cell-based protein expression systems rely on the host cell machinery – with its inherent limitations – to produce proteins of interest. First, cells are transfected with the DNA of the desired protein, and then a stably expressing cell line is selected and cultured to produce that protein. Although relatively simple and easy to control, this process is time-consuming, must be optimized for each protein, and is prone to contamination. From initial conception to harvesting a protein of interest can take up to 6 months, while toxicity resulting from protein over-expression can sometimes result in low or no protein yields at all (see figure 1). Cell-free protein expression systems are emerging as a favorable alternative due to their ability to overcome these shortcomings.

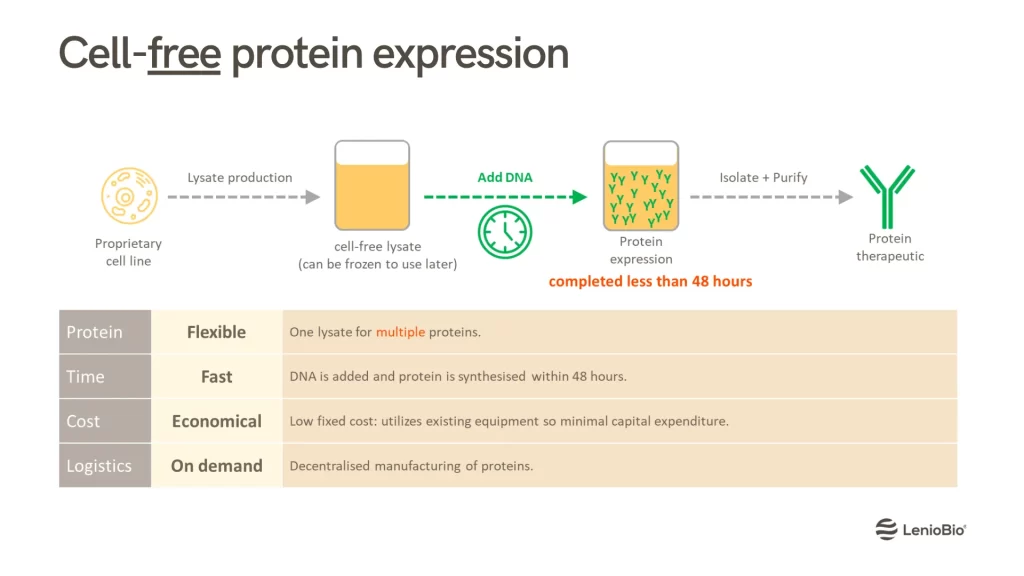

Cell-free protein expression (CFPE) is a method of producing proteins by harnessing the cell’s RNA and protein synthesis machinery in a cell-free system. This in vitro system lacks an external cellular membrane and a functional genome allowing flexible expression of a wide range of proteins in varied conditions [1] (see figure 2). The components of a typical CFPE system include a cellular lysate and DNA expressing the protein of interest, along with other mandatory substrates such as energy sources, nucleotides, amino acids, salts, and cofactors [2].

Impossible to express? Not anymore

Proteins are a diverse class of biomolecules – some are no fuss and easy to express, while others are difficult or even impossible to express. One of the most exciting aspects of cell-free protein expression is its potential to enable and expand the production of proteins that are difficult or impossible to express in living cells, particularly the ones that cause toxic effects. While being less amenable to cell-based expression, these proteins are often drug targets or offer promise as therapeutics.

In addition, cell-free systems allow proteins to be produced in a more controlled and defined environment. This allows for greater control over the final protein product and the possibility of incorporating novel modifications.

Cell-free protein expression systems – the unique advantage of plant-based systems

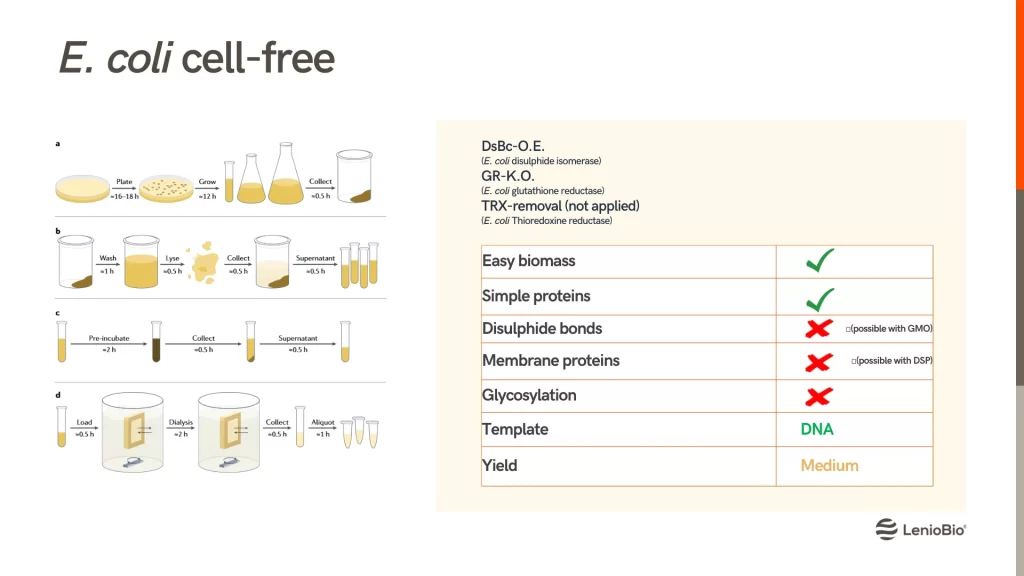

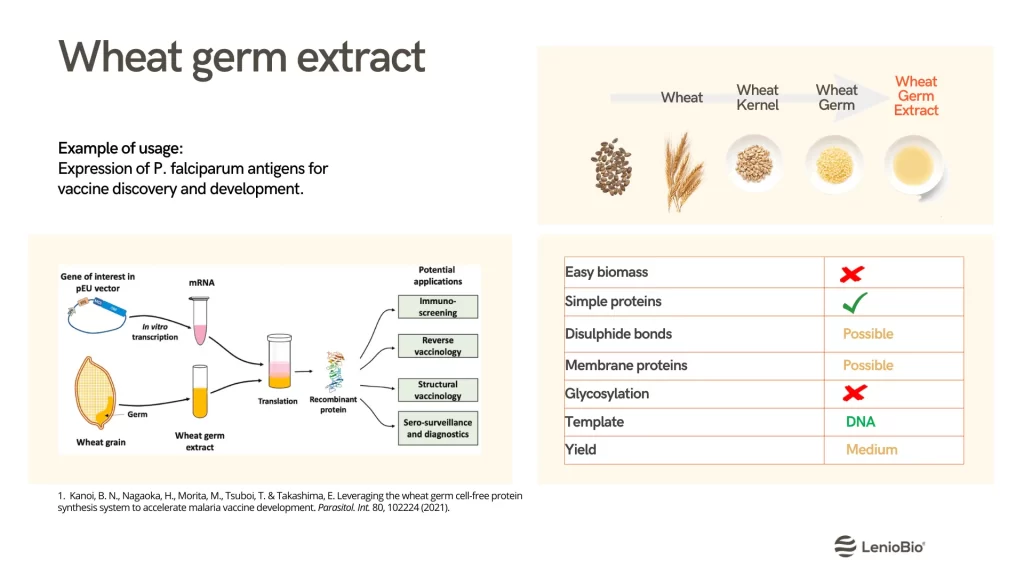

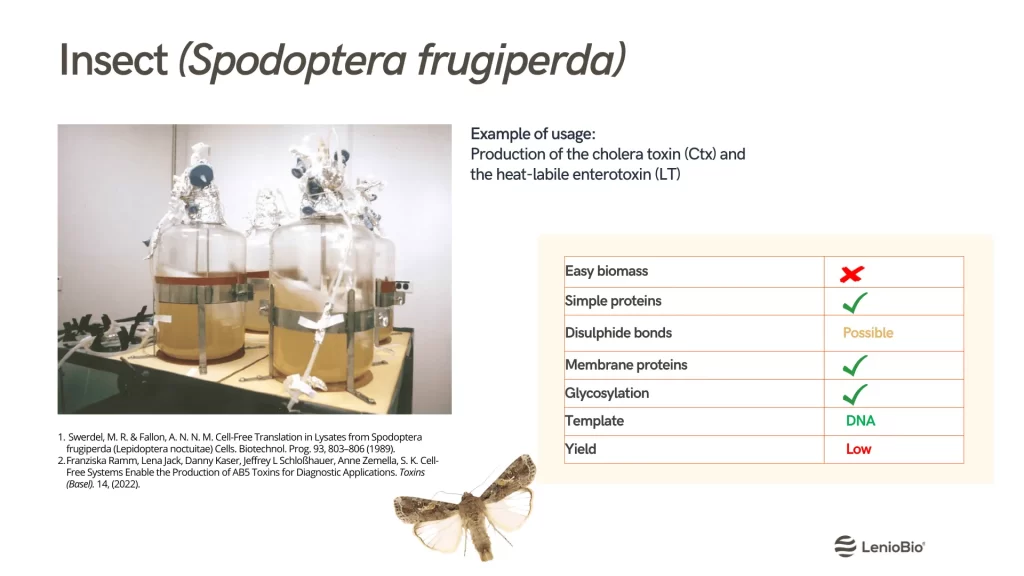

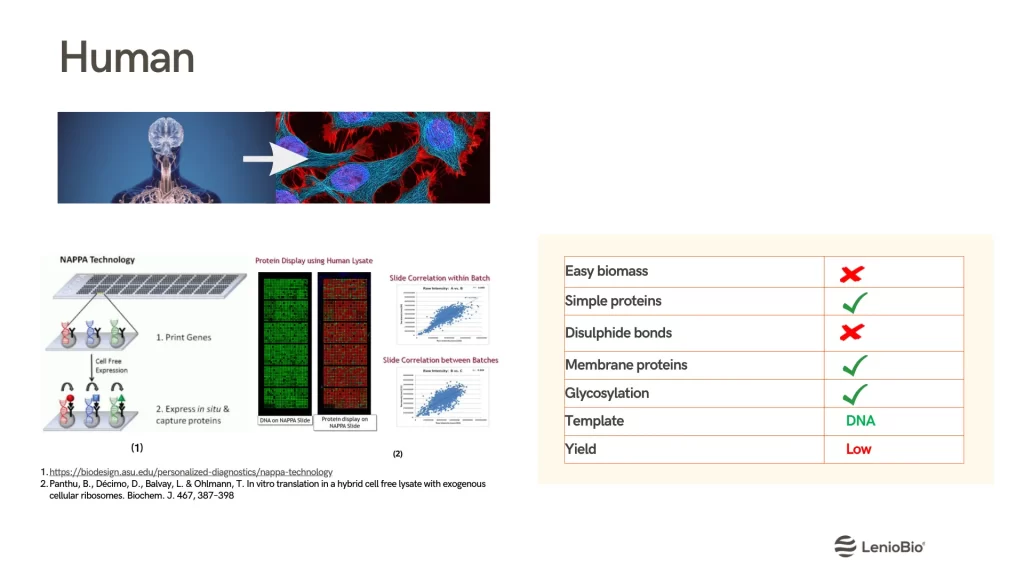

The first cell-free system was reported over 60 years ago by Nirenberg and Matthaei in a discovery that turned out to be a fundamental breakthrough in modern biology – the genetic code and the link between RNA and protein synthesis [3]. They created an E. coli-based “cell-free environment” to “crack” the genetic code. Since then, various platforms based on cell extracts from different organisms have emerged. The most popular are based on extracts from the bacterial, archaeal, plant, mammalian, and human cell lines.

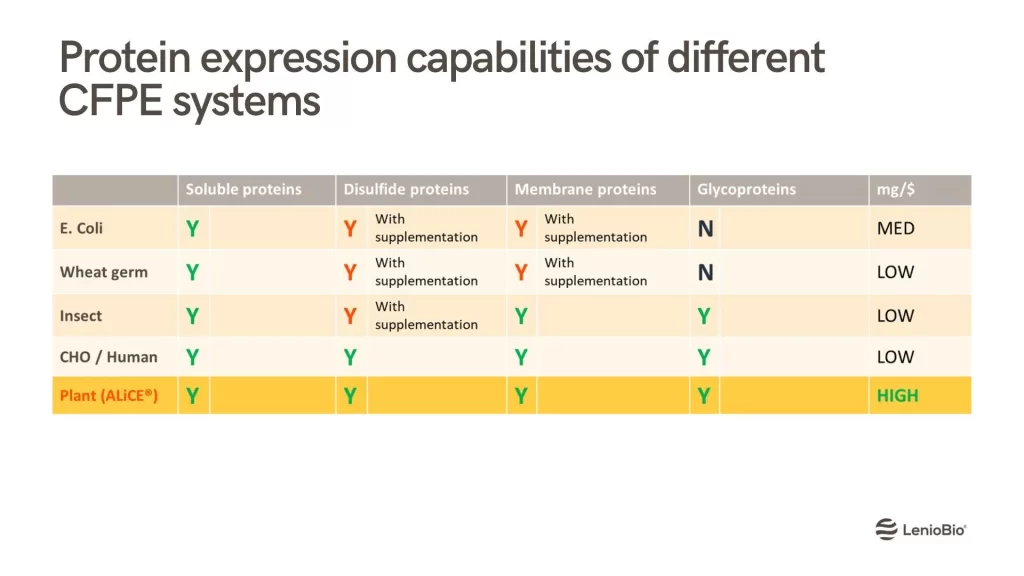

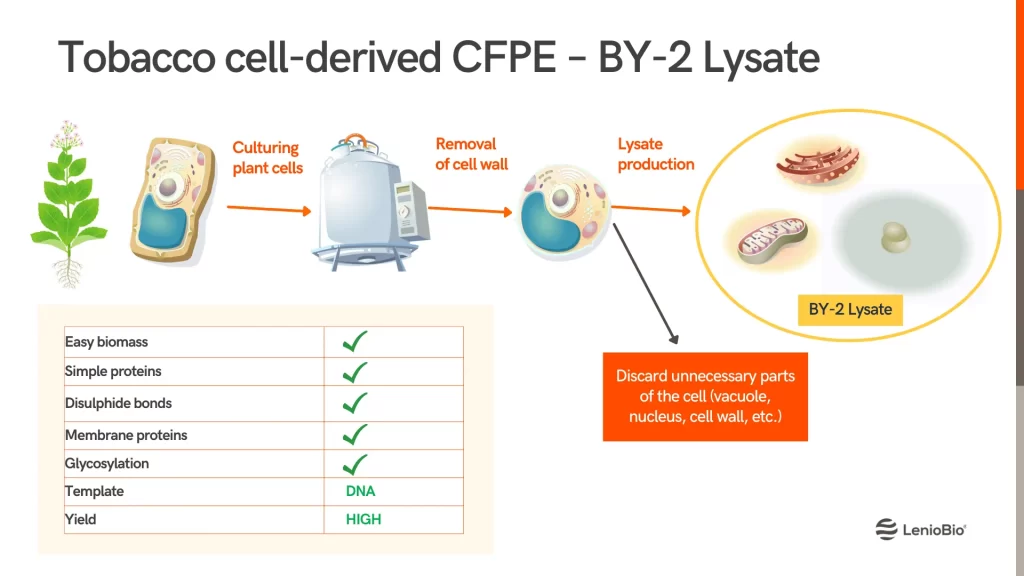

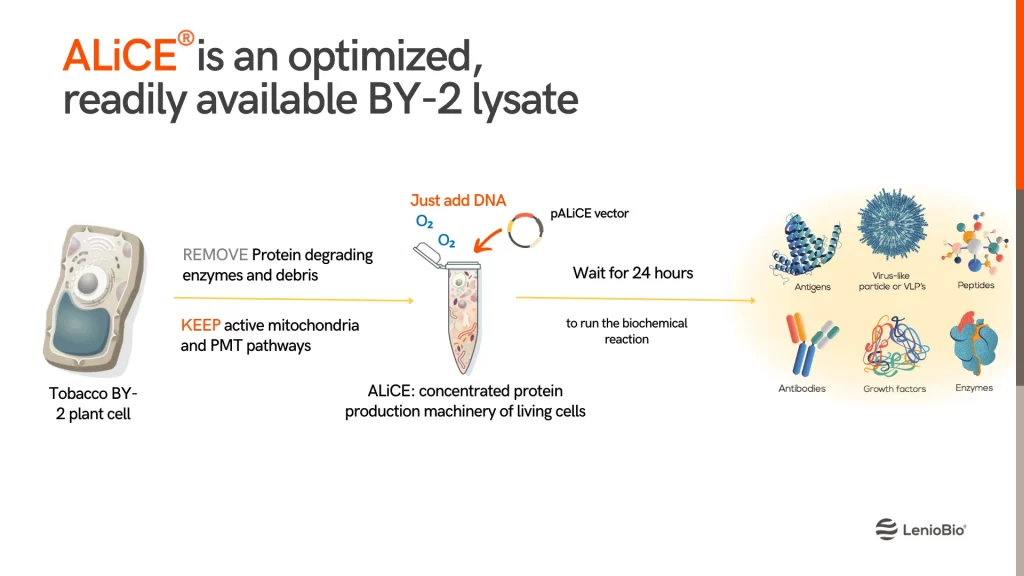

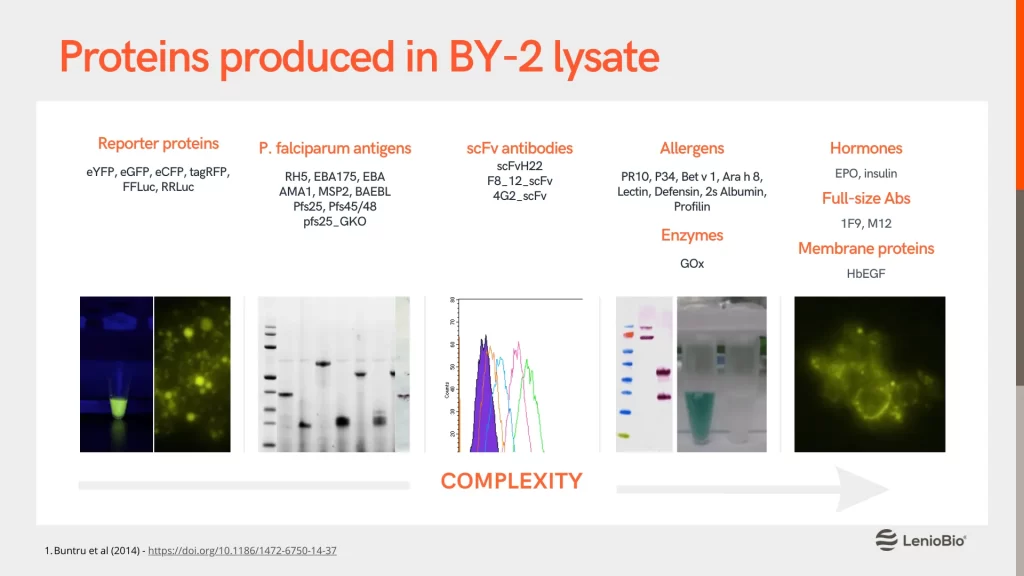

The choice of a cell-free protein expression platform depends on the type and nature of the protein of interest. For example, insect- and human-based systems are best suited for expressing membrane proteins and glycoproteins. Among cell-free systems, plant-based CFPE systems are unique in their ability to produce a wide range of proteins – including difficult-to-express proteins – at a high yield [4]. For an overview of available CFPE systems, see figures 4-9.

What are the advantages of a plant-based cell-free system?

Plants are complex eukaryotic systems with protein production and processing machinery to match. The complexity of their protein production machinery makes them inherently more capable of producing mammalian proteins than CFPE derived from bacteria or yeast, particularly those with post-translational modifications. Moreover, proteins expressed in plants are less likely to produce immunogenic responses in humans and animals than proteins produced in bacterial systems. These attributes, combined with the emergence of high-yielding plant-based CFPE systems capable of operating at scale, make them an attractive choice even compared to mammalian systems.

A high-yield, scalable CFPE system

ALiCE®, manufactured by LenioBio GmbH, is a high-yielding eukaryotic CFPE platform based on a Nicotiana tabacum BY-2 lysate. The system can produce any protein class, no matter how complex, quickly and easily. ALiCE® has all the machinery necessary to install complex post-translational modifications like glycosylation and disulfide bonding without specific optimizations. LenioBio, has also tackled the issue of scalability, having announced successful scaling of their platform to produce up to 3 grams per liter of complex, functional proteins in reaction volumes of up to 10 liters. This is a significant step toward achieving commercial-scale cell-free protein manufacturing.

With the introduction of platform technologies like ALiCE®, cell-free expression systems are beginning to change the status quo in protein production. From enabling protein drug candidates to be discovered faster to getting promising candidates more quickly to clinical trials, CFPE is set to transform the protein production industry.

References

- Gregorio, N. E., Levine, M. Z., & Oza, J. P. (2019). A User’s Guide to Cell-Free Protein Synthesis. Methods and protocols, 2(1), 24. https://doi.org/10.3390/mps2010024

- Khambhati, K., Bhattacharjee, G., Gohil, N., Braddick, D., Kulkarni, V., & Singh, V. (2019). Exploring the Potential of Cell-Free Protein Synthesis for Extending the Abilities of Biological Systems. Frontiers in bioengineering and biotechnology, 7, 248. https://doi.org/10.3389/fbioe.2019.00248

- Nirenberg, M. W., & Matthaei, J. H. (1961). The dependence of cell-free protein synthesis in E. coli upon naturally occurring or synthetic polyribonucleotides. Proceedings of the National Academy of Sciences of the United States of America, 47(10), 1588–1602. https://doi.org/10.1073/pnas.47.10.1588

- High-yield has been proved only in the ALiCE® system.